15 Dec 2023 / News

Economic viability of AlSiCal technology: Being sustainable and innovative can be also a profitable business

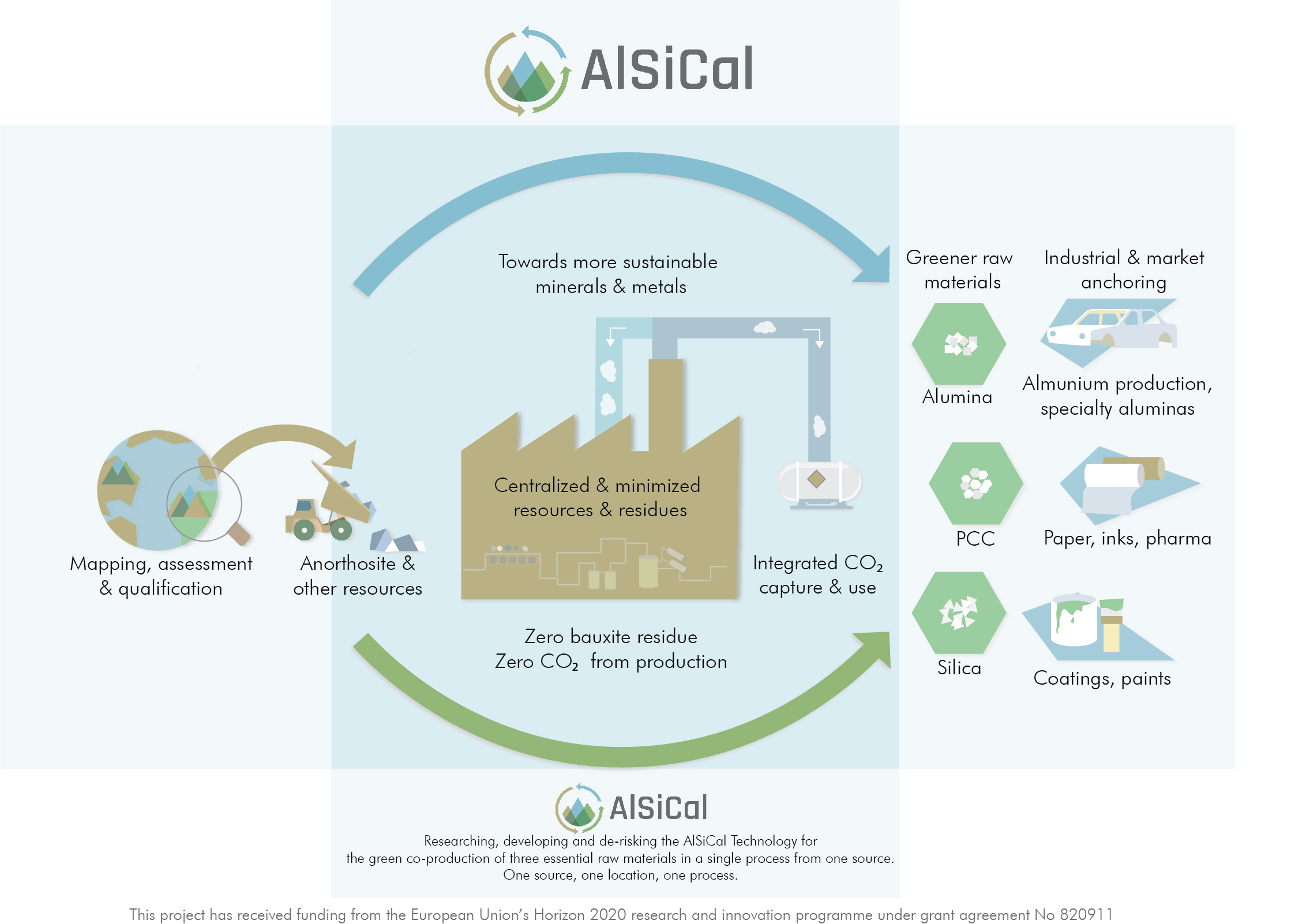

As you might already know, AlSiCal aims to revolutionize the metals and industrial minerals sectors by implementing a zero-waste and negative-to-zero CO2 emissions process that transforms anorthosite rock into three valuable minerals – alumina, silica, and PCC (alternatively CaO or wollastonite, as feasible variations of it). We are excited to announce that the feasibility study for the AlSiCal project has been performed and analysed for three different process variations: AlSiCal-IFE, AlSiCal-AV Labs, and AlSiCal-Wollastonite. The study considered two different energy scenarios for each of them: a fully electrified process with renewable energy and hydrogen versus a process powered by natural gas.

The economic viability of the AlSiCal process

The economic viability of each process variation was carefully assessed, including detailed sensitivity analysis for all key influencing factors, and calculating the profit margin for different scenarios. Additionally, we calculated the profit margin that would result from a virtual process, emulating the production of the same products´ volumes by existing Best Available Technologies (BAT). In other words, as if three plants of current processes combined (the Bayer process and current silica and PCC plants) were producing the same products as from the AlSiCal technology. This comparison gives a comprehensive understanding of the AlSiCal technology potential and its competitiveness in the existing market.

Furthermore, the study utilized estimated CAPEX (capital expenditures) and OPEX (operating expenses) to extract economic indices such as NPV (net present value), IRR (internal rate of return), ROI (return on investment), and other relevant indices.

Findings of feasibility study

The findings of the feasibility study have revealed that the AlSiCal-IFE process, optimized for realistic processing capacity and material consumption, shows promising economic prospects. This indicates the potential of the AlSiCal project to significantly impact the mineral industry.

Despite the low Technology Readiness Level (TRL) of AlSiCal, which entails certain degree of uncertainty, the results are very encouraging as to further pursue the development of AlSiCal technology towards industrialization and commercialization. By transforming anorthosite rock into alumina, silica, and PCC (alternatively, CaO or wollastonite by certain configurations), AlSiCal has the potential to fundamentally change the way these minerals are produced, drastically reducing waste and reliance on traditional mineral sources, especially on bauxite (a Critical Raw Material) and alumina imports to EU and EFTA. The positive economic feasibility of the AlSiCal IFE process provides us with a clear picture of the project’s optimistic prospects.

This work has been successfully led and performed by AdMiRIS, in collaboration with IFE and Unizar, and represents an important milestone of the project.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 820911

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 820911